01. What is Mean by Electrical Maintenance?

Ans: For continuous operation of the electrical system we have to repair, diagnosis a fault, observation can be done by Maintenance to run it continuously.

02. What are the types of Maintenance?

Ans: The types of maintenance are:

a. Preventive Maintenance

b. predictive maintenance

c. Corrective maintenance

03. How we can check cable continuity?

Ans: It can be checked by using Multimeter. Keeping the knobs on cable both sides and when there is a sound then we decide cable is good.

04. What are the faults occur on the HT breaker?

Ans: Overvoltage, overcurrent, undervoltage, earth fault, DC supply fail.

05. How you can take megger (IR) value?

Ans: Megger value can be taken with phase to phase and phase to earth. i. e. R-Y, Y-B, B-R and R-E, Y-E, B-E.

06. What is mean by PERCOW or work permit?

Ans: While doing any work on a live electrical system you need a PERCOW means a permit for work commissioning from the authorized person.

07. What is the toolbox talk?

Ans: During the maintenance before work starts it is the responsibility of Engineer to give toolbox talk means which section is disconnected, from where there is supply and work within the cordon area.

08. What is mean by changeover?

Ans: If we want to take shut down on a particular section of substation than we have to manage load or shifting load from one source to another or one transformer to other transformers.

09. How many times Maintenance is done?

Ans: It was done by Daily, weekly, Monthly, Quarterly, and yearly.

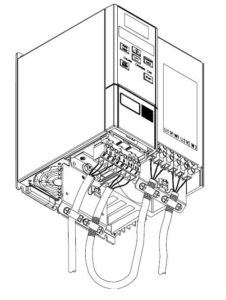

10. What are the types of panels?

Ans: HT, LT, sub LT, RTU( Remote terminal unit) APFC (Automatic power factor correction ), MCC( motor control circuit), and PCC( power control circuit ).

11. What are the six golden rules of safety?

Ans: The six golden rules of safety are:

1. Disconnect all sources of power.

2. Follow Log out tag out (LOTO) on a particular feeder

3. Check the supply continuity by using an HT detector.

4. Do all phases properly earthed by using the earth rod.

5. Cordon the adjacent area.

6. Ensure proper personnel is deployed for work.

12. Electrical shock caused by voltage or current?

Ans: It may be caused by current not voltage.

13. Which tools are used in Electrical Maintenance?

Ans: Multimeter, Megger, Spanner ser, Rachet set, HT, LT hand glows, Tester, clamp meter, insulation tape, torch, plier, nose plier, alen key, etc.

14. What is the difference between Dry-type transformer & oil type transformer?

Ans: In dry type air is used as an insulating medium, the cost is high, less maintenance, used in public places.in oil type transformer oil is used as insulating media, the cost is less, maintenance more, high efficiency, etc.

15. Tell me the ratings of Transformer, induction motor, DG, generator?

Ans:

a. Transformer in KVA, MVA.

b. Motor in KW MW.

c. DG in KVA, MVA.

d. Generator in KVA, MVA.

e. UPS in KVA.

16. What is the lamp indication on HT breakers?

Ans: ON indication, OFF indication, breaker in-service indication, the breaker in test position indication, breaker trip position indication, Spring charged indication.

17. What are the types of power?

Ans:

1. Real or active power

2. Reactive power

3. Apparent power.

18. What are MCC and PCC?

Ans: MCC: motor control circuit.

PCC: a power control circuit

PCC is more powerful than MCC.

19. Do you know the difference between AIS and GIS?

Ans: AIS: Air-insulated substation. It uses air as an insulating media, the cost is less, Maintenance is more, space required more that’s why the demand for AIS is less nowadays.

GIS: Gas-insulated substation SF6( Sulfur hexafluoride) gas used as an insulating media, space required less, less maintenance, the cost is high, required a skilled person nowadays in the compact area where space is less there GIS is used.

20. Tell me what parameters you are going to check while doing maintenance of dry type transformer?

Ans: During maintenance first you have to shut down transformer after that follow six golden rules, then you have to clean it by using blower after that clean it with cotton wastes, after that check the tightness of HV side and LV side after that take megger or IR value and noted.

21. Can you give the classification of faults in the power system?

Ans: There are mainly two types of faults:

1. Series faults

a) Single conductor open

b) Two conductor open

2. Shunt fault

A) Balanced fault

1) Three-phase fault

2) Three-phase to ground

B) Unbalanced fault

1) line to ground fault

2) The line to line fault

3) Double line to ground fault.

22. What is the long-form of HVAC, STP, WTP, BMS, and UPS?

Ans:

HVAC: Heating, ventilating and air conditioning

STP: Sewage treatment plant

WTP: water treatment plant

BMS: Building Management system.

UPS: Uninterrupted power supply.

23. Why we installed the capacitor bank?

Ans: To improve the power factor.

24. What is the earthing pit? Which materials are used for earthing pits?

Ans: As we know current always follow the path of least resistance and to divert the maximum current away from an electrical circuit earthing pits are necessary.

The material used is charcoal, salt, and water.

25. How DG start?

Ans: It can be started by Manually or Automatic mode.

26. Do you know DG Check?

Ans: yes,

1.) A check

2.) B check

3) C check

4) D check

27. What is SCADA? How it is used in a substation.

Ans: Supervisory control and data acquisition.

SCADA is remote control of your substation were you able to know the current status of all substation equipment. You can also make the on and off status of any equipment like Breakers, Transformers, Incomers, APFC, etc.

28. What is bus coupler, busbar, isolator, and incomer?

Ans: It a device where it is coupled with another device without interrupting the system. In case of emergency for shifting the load we can on the bus coupler.

Busbar: It is a bundled conductor on which several( more than two) conductors are mounted.

Isolator: It can be operated only in no-load condition and installed at before and after the circuit breaker.

Incomer is a nothing but breaker but incoming supply is given to this breaker, if this breaker tripped, all feeders which are on this incomer are off.